Driving Profitability- Productivity Tutorial

Driving Profitability- Productivity Tutorial

➤ Are you in the Service or Manufacturing sector?

➤ Are you striving to Grow, Thrive and Lead today’s competitive markets?

➤ Are you working to drive your Profitability and produce, Better and More with Less?

➤ Are you looking to increase your ROI and Increase your Revenue?

➤ Are your looking to Reduce your Spends without compromising your market demands, customer expectations or employee satisfaction?

➤ Are you looking to Run Lean Operations on all aspects of your business: (LD&T, Manufacturing, Sales, General and Administration, Technology, Marketing and Advertisement, Value Engineering, Commodity Compressible, Capital Expenditure?)

➤ Our Competent team of Scholars and consultants partnered with several of the 500 Fortune companies to engage their massive teams to drive productivity that range between $1Million and $10Million captured savings per year.

➤ We at chools provide various consulting schemes, effective strategies and vigorous knowledge that will guide you in delivering your productivity objectives.

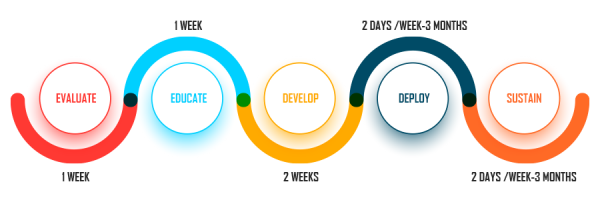

Productivity tutorial is the first milestone to establish your productivity journey and Cost optimization advancement. Through this consulting service, the organization will be able to:

We will drive world-class end results desired by our clients through

This service is best deployed by entities that are at early stages of their productivity journey and aim to expand the productivity mindset to all stakeholders and workers of the organization bottom- top; Left right center, and to have a vigorous system in place to assist them in driving their productivity journey.

➤ Companies that collaborated with CHOOLS and deployed OUR productivity system achieved 6-10% Savings of their base spend.

➤ Develop the capability of your teams and spread a mindset of cost reduction, elimination of losses to drive productivity opportunities

➤ Acquire a well-established sustainable productivity system in place.

A Leading Juice producer hired Chools to improve the overall equipment efficiency for their production lines. Chools consultant started with the going through the Loss analysis tree to identify biggest losses. One of the biggest opportunities was identified as a Cleaning in Place (CIP) activity on their Highest volume PET Line. The CIP took 5 hours vs. a standard of 2 hours benchmarking with other affiliates This had an impact of 6% Loss on OEE. The OEE was 75%, short from the annual operating plan by 6%.

After looking at the historical Data, we conducted a Pitstop event to measure all tasks and analyze with the line crew the opportunities and improvement plan for the CIP activity, which consists of 5 steps (Cold CIP, Hot CIP, Chemical Sanitization, Cold CIP, External Cleaning). The following was identified

✔ Optimize scheduling to reduce number of CIP through improving forecast accuracy measure.

✔ Optimize sanitization Matrix.

✔ Modify Piping diameters to increase flow and decrease time.

✔ Optimize temperature of Hot water cleaning step to reduce waiting time for getting filler Hot, which also influenced Fuel and water consumption.

✔ Reduce time of steps validated by Quality team.

✔ Eliminate first Cold step cleaning.

✔ Conduct external cleaning in parallel to last CIP step through installing water nozzles on filler.

The CIP Time was reduced from 5hrs to 2hrs, and number of CIP events were reduced from 156 to 78 times per year. The Loss on OEE contributed by CIP for this Juice line was reduced from 6% to 2%. The $/case for that line and SKU was reduced by 17%. In addition, Water consumption was improved by 11% and Fuel consumption by 5%.

A Liquid Hand Soap Manufacturer with an annual production of 255MM tones was aiming to increase its profitability and revenue through improving its overall equipment efficiency of their four production lines. The OEE for the plant was 71%, short from the annual operating plan by 4%. Chools consultant started with the going through the Loss analysis tree to identify biggest losses. Two of the lines were not meeting their OEE target and had the largest volumes and therefore Chools focused with the team on those two lines.

Chools chose to conduct a Focused improvement event ( A DT5 event- Check our other services ) on one of the lines, and start and Autonomous Maintenance program on the other line (Which showed a high downtime due to minor stops on the machines).

As part of the DT5 Focused Improvement event, our consultant used the 4 DT5 tools to identify opportunities and the below was found:

✔ 11 major equipment defects that reduced reliability of the machines were identified.

✔ Raw Material Variability that is reducing the 7.7oz Line efficiency by 15%.

✔ The top three Equipment OEE loss contributors were identified and a root cause analysis was conducted for problem solving.

✔ Accumulation table cannot support downstream equipment downtime on the 11oz size.

The above gaps were fixed and OEE improvement driven

Autonomous Maintenance

After establishing the AM team and training them, the team formed the required AM tools and standards to execute the program: CILT (Cleaning, Inspection, Lubrication, Tightening), Centerlines, One Point Lessons, safety maps and Job Hazard Analysis. The lines were scheduled every shift to execute the established standards and reduce downtime caused by machine reliability.

The OEE of the plant increased by 10 % across the course of 1 year, driven by the improvement on both lines. The FI DT5 event drove a 6% improvement on the Line 1 and AM drove 7% improvement on Line 2. This resulted in a reduction in the $ Cost/case by 17% increasing plan profitability. In addition, plant labor productivity increased by 31%.